Palm Oil Production Process: A Step-by-Step Guide

Fractionation: Fractionation is an optional step that can be used to further refine the palm oil and produce specific fractions with different properties and applications. Packaging and Distribution: Once the palm oil has been refined and fractionated (if applicable), it is packaged and distributed to customers worldwide.

Get Inquiry

(PDF) Polyunsaturated Fatty Acid Fractionation from Crude Palm Oil (CPO)

Polyunsaturated Fatty Acid Fractionation from Crude Palm Oil (CPO) December 2021 Processes 9(12):2183 DOI:10.3390/pr9122183 License CC BY 4.0 Authors: Zuchra Helwani

Get Inquiry

LIFE CYCLE ASSESSMENT OF REFINED PALM OIL PRODUCTION AND FRACTIONATION (Part 4)

The life cycle assessment (LCA) study on refined palm oil (RPO) and its fractionated products is part of the sustainable solution provided by the Malaysian palm oil industry. The study was conducted according to established ISO (International Standards Organization standards) for LCA. The system model for this LCA study was developed and

Get Inquiry

Development of dual stage solvent fractionation as an approach to concentrate carotenoids from crude palm oil with high recovery: The potential

Solvent fractionation of crude palm oil (CPO) Briefly, 50 g of CPO was melted at 70 C and mixed with a solvent. The opening was tightly sealed with aluminum foil to prevent solvent evaporation. Fractionation was then carried out at 25 C under constant stirring at

Get Inquiry

(PDF) Life cycle assessment of refined palm oil production and fractionation (Part 4)

LIFE CYCLE ASSESSMENT OF REFINED PALM OIL PRODUCTION AND FRACTIONA TION (Part 4) TABLE 2. REFINED P ALM OIL PRODUCT SYSTEM AND THE ASSOCIA TED DAT A TYPE/SOURCE (data collected in the period 2007/

Get Inquiry

Good Quality New Cpo Palm Oil Fractionation Plant South Africa

China Buy Cpo, China Buy Cpo Manufacturers and Suppliers ... Good Quality New cpo palm oil fractionation plant south africa. Zhengzhou Qi'e Grain And Oil Machinery Co., Ltd. US $30000-300000 / Set . 1 Set (Min. Order) Contact Supplier . Transaction Level .

Get Inquiry

Palm Oil and Palm Kernel Oil Refining and Fractionation Technology | Request PDF

Palm Oil and Palm Kernel Oil Refining and Fractionation Technology. December 2012. DOI: 10.1016/B978-0-9818936-9-3.50015-0. Authors: V¨¦ronique Gibon. Desmet Ballestra Group. To read the full-text

Get Inquiry

Palm Oil Dry Fractionation process 2 from Desmet Ballestra | Download Scientific Diagram

Physical refinery The process flow diagram for palm oil physical refining is shown in Fig. 2. The physical refinery is where CPO, that is received from the mills, is processed. The CPO first goes

Get Inquiry

Processes | Free Full-Text | Polyunsaturated Fatty Acid Fractionation from Crude Palm Oil (CPO)

Crude Palm Oil (CPO) is the result of the process of pressing the flesh of the palm fruit or mesocarp [ 2 ]. The components contained in CPO are almost 95% triglycerides, 4.5% diglycerides, and 0.9% monoglycerides. Variations in this composition depend on the species, growing location, and age of the oil palm [ 3 ].

Get Inquiry

Making the Palm Oil Industry Greener - The Chemical Engineer

Palm oil in Malaysia. Introduced to Malaya (now Malaysia) as a commercial plant in 1917, the nation¡¯s palm oil industry has grown from humble beginnings to become the world¡¯s second-largest palm oil producer (behind Indonesia), exporting around 30% of the world¡¯s supply. About 40% of Malaysia¡¯s palm oil output is produced by smallholders.

Get Inquiry

Palm Oil Fractionation - palmoilmillplant.com

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0¡æ to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Get Inquiry

Palm Oil Dry Fractionation process 2 from Desmet Ballestra

Physical refinery The process flow diagram for palm oil physical refining is shown in Fig. 2. The physical refinery is where CPO, that is received from the mills, is processed. The CPO first goes

Get Inquiry

A Review on the Fundamentals of Palm Oil Fractionation: Processing

The various fraction of palm oil allows it to be used in different types of food products such as margarine, frying oil, and cocoa butter substitute. In fractionation, proper control of the fractionation conditions is important to produce the fractions with desirable stearin and olein quality.

Get Inquiry

Palm Oil Production Process: A Step-by-Step Guide

Fractionation: Fractionation is an optional step that can be used to further refine the palm oil and produce specific fractions with different properties and applications. Packaging and Distribution: Once the palm oil has been refined and fractionated (if applicable), it is packaged and distributed to customers worldwide.

Get Inquiry

INDOPALM

ABOUT US. PT. Pacific Indopalm Indutries established in Dumai city - Riau province, East cost of Sumatra Island, the biggest volume Refinery operation area and the largest palm oil products exporting city in Indonesia. Established in December 2009 and in 2013 additional plants installed to increase the capacity by 120% to cover the palm oil

Get Inquiry

cpo fractionation - Huatai Palm Oil Production Line

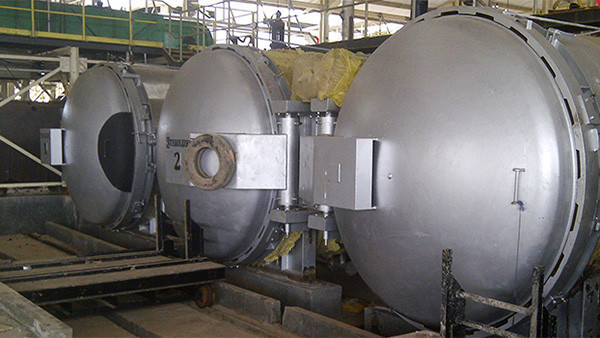

For Palm Oil Refinery Plant, Fractionation Process is required in which palm olein and palm stearin are separated by scientifically cooling the refined palm oil by chilling plant and then filtering the oil. For this purpose crystallizing vessel is used in which chilling pipe coils cool the oil for fractionation. Palm stearin crystals are formed

Get Inquiry

How to Choose Palm Oil Fractionation Machine and Process?

Dry Fractionation of Palm Oil. Dry fractionation process for palm oil production is one of the most economical methods. It refers to the method of slowly cooling the dissolved oil to a certain degree without adding any solvent, and then filtering, separating and crystallizing out the solid ester. Dry fractionation can be divided into three

Get Inquiry

Palm Oil and Palm Kernel Oil Refining and Fractionation Technology

Crude, degummed bleached, or fully refined palm kernel oils can be processed with this technology ( Calliauw et al., 2005) ( Table 12-M ). The saturated fatty acid content is increased from ¡«80% in the palm kernel oil to 93¨C96% in the palm kernel stearins; the lauric and myristic fatty acid contents go up to 80%.

Get Inquiry

Palm Oil and Palm Kernel Oil Refining and Fractionation Technology

Palm olein is a resulting liquid fraction from fractionation of palm oil with a relatively high oleic acid content of about 41.5¨C47.7 % and is more cost-effective compared to commercial oleic acid as a high proportion of palm olein can be obtained in one single step of fractionation (Derawi et al., 2014; Gibon, 2012; Tarmizi and Ismail, 2008).

Get Inquiry