Edible Oils | Sustainable Palm Oil | Edible Oil Processing | Olam Agri

Combined with our advanced risk management expertise and tools, we¡¯re able to help manage supply and risk for customers across Africa, the Middle East, Europe and Asia. We operate edible oil processing and refining in Nigeria where we refine crude vegetable oils and market refined, bleached and deodorised palm oil, palm olein and refined

Get Inquiry

Vegetable Oil Refining | SpringerLink

Crude vegetable oils and fats are mainly triacylglycerols (around 95%) along with impurities and variable amounts of other minor constituents. To ensure the oils are safe for human consumption, the crude oils are subjected to several purification steps, known as refining process. The aim of this process is to eliminate the unwanted constituents

Get Inquiry

About | Madagascar Oil

Having been in country since 2004, Madagascar Oil is Madagascar¡¯s leading and longest operating oil and gas company. In 2015, the Company was the first oil and gas company in the country to be awarded a development license when it received a 25-year license to develop Block 3104 (Tsimiroro). Additional extensions to this license enable a

Get Inquiry

baobab seed oil refinery plantry zimbabwe with 1-5tph | Oil Press And Oil Production Line For Vegetable Seeds

Oil Expeller HotCold Press Palm Kernel Oil Expeller Machine/mustard Seed Oil Expeller Machine$2,200.00-$2,450.00/ Set, 1.0 Sets(Min. Order),rapeseed oil extractor and refining machine.Philippines Oil Philippines Coconut Baobab Seeds Canola Olive Pressing

Get Inquiry

Vegetable Oil vs Refined Oil: Difference and Comparison

Refined oil can be made from various sources, including vegetable oil. Vegetable oil is considered to be healthier than refined oil because it contains more nutrients. Vegetable oil is made from seeds and fruits or other vegetable sources. Vegetable oils are not only used for cooking but also used in the cosmetic industry.

Get Inquiry

Edible oil refining

Edible oil refining is a set of processes or treatments necessary to turn vegetable raw oil into edible oil. Raw vegetable oil, obtained from seeds by pressing, solvent extraction, contains free fatty acids and other components such as phospholipids, waxes, peroxides, aldehydes, and ketones, which contribute to undesirable flavor, odor, and appearance; for these reasons, all the oil has to be

Get Inquiry

Physical Refining of Vegetable Oils - ScienceDirect

A physical refining deodorizer is the same as a conventional deodorizer, but modifications are made to handle the higher FFA load, owing to the fact that the FFAs were not neutralized. A brief definition of physical refining is: FFAs are removed in a physical refining deodorizer, with no neutralization of the FFAs in a previous processing step.

Get Inquiry

(PDF) Refining Vegetable Oils: Chemical and Physical Refining

Advantages and drawbacks of both chemical and physical re?ning. were discussed in the light of recent literature. Physical re?ning has several advantages over chemical one. 1. Introduction

Get Inquiry

Advances in Treatment of Vegetable Oil Refining Wastes | Request PDF

The vegetable oil refinery wastewater (VORWW) creates an environmental problem in terms of threat to aquatic life due to high organic and inorganic content (Donald et al. 2019). Hung and Kaya

Get Inquiry

Edible vegetable oils from oil crops: Preparation, refining

Vegetable oil is rich in triglycerides and contains fatty acids and micronutrients (tocopherols, phospholipids, sterols, carotenoids, etc.) [1]. It has been widely used in the cooking, food, pharmaceutical and cosmetics industries, among others [2]. The annual growth rate of global demand for vegetable oil was 5.14% from 2020 to 2025 [111].

Get Inquiry

Production process, methods of extraction, and refining technologies

For the refining of crude vegetable oils, there are two main routes: the chemical and the physical refining. Some by-products of low commercial value are obtained through these refining processes. Important amounts of by-products such as soapstock, deodorizer fatty acid distillates, and acid oil are produced from the oil refining processes ( Piloto-Rodriguez et al., 2014 ).

Get Inquiry

Refining Vegetable Oils: Chemical and Physical Refining

Degumming is a crucial step in the refining process of vegetable oils . It allows the elimination of ¡°gums¡± or ¡°mucilage,¡± composed mainly of phospholipids from the crude oil as well as compounds such as carbohydrates, proteins, and trace of metals [9, 34]. Phospholipids or phosphatides are naturally present in oils.

Get Inquiry

A Review on Vegetable Oil Refining: Process, Advances and Value

Crude oils obtained by oilseed processing have to be refined before the consumption in order to remove undesirable accompanying substances. The traditional alkali refining is often replaced by

Get Inquiry

FEDIOL Code of Practice on vegetable oil and fat refining for food

The crude oil is treated with food grade processing aids (acids) and/or water, which leads to hydration of the main part of the phosphatides, proteins, carbohydrates and traces of metals. The concentration of the processing aids depends on the quality of the crude vegetable oil. The hydrated gums are removed by centrifugal force from the oil.

Get Inquiry

Vegetable Oil Refining | SpringerLink

Crude vegetable oils and fats are mainly triacylglycerols (around 95%) along with impurities and variable amounts of other minor constituents. To ensure the oils are safe for human consumption, the crude oils are subjected to several purification steps, known as refining process. The aim of this process is to eliminate the unwanted constituents

Get Inquiry

Vegetable Oil Processing

The vegetable oil processing industry involves the extraction and processing of oils and fats from vegetable sources. Vegetable oils and fats are principally used for human consumption but are also used in animal feed, for medicinal purposes, and for certain technical applications. The oils and fats are extracted from a variety of fruits, seeds

Get Inquiry

Refining Vegetable Oils: Chemical and Physical Refining

two main industrial technologies used for vegetable oils¡¯. re?ning, namely, chemical re?ning and physical re?ning. Chemical re?ning removes free fatty acids by soda neu-. tralization

Get Inquiry

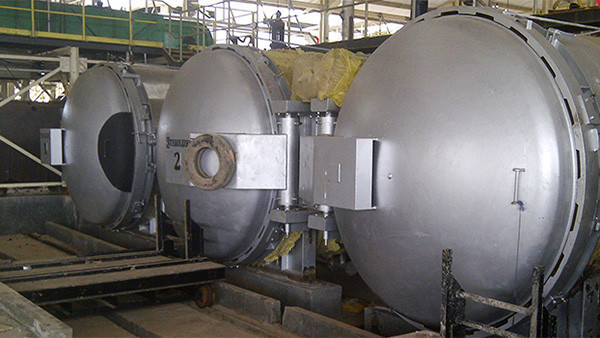

An example of full processing flow chart for a palm oil refining

An overall summary of the palm oil refining process is an example of vegetable oil processing and depicted in Figure 1 [50][51][52][53]. Oil extraction is the unit operation performed to separate

Get Inquiry

Physical Refining of Vegetable Oils - ScienceDirect

Physical refining of vegetable oils offers great opportunity for green vegetable oil processing, and is a contribution toward sustainability of oil mills and refineries, as supported by the following. . The process has a much smaller carbon footprint, less equipment required, considerably less capital cost, and lower cost of automation.

Get Inquiry