9.11.1 Vegetable Oil Processing - U.S. Environmental Protection Agency

soybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oil refining. Oilseed Handling/Elevator Operations - Figure 9.11.1-1 is a schematic diagram of a typical soybean handling/elevator operation that precedes the

Get Inquiry

Solvent extraction process of soybean - Edible Oil Expeller Machinery

The first stage is mainly to dissolve the oil in the damaged cells by solvent. The extraction amount is large and the time is short (15~30 minutes), and the total oil content can be extracted from 85% to 90%.In the second stage, solvents are needed to penetrate into the unspoiled cells for a long time with low efficiency.

Get Inquiry

Soybean seed Continuous Solvent Extraction Plant - YouTube

Pemac Projects soybean seeds continuous solvent extraction plant in operation in east AfricaThis video shows how we used cutting-edge technology to extract o...

Get Inquiry

Solvent Extraction

In comparison, solvent extraction with hexane (the primary solvent used worldwide) will remove all but about ?% of residual oil, uses less horse power, and requires less maintenance. It is relatively efficient and reliable, and this is one reason why solvent extraction is the primary means of separating large tonnages of oil from protein meal.

Get Inquiry![[pdf] evaluation of the parameters affecting the solvent extraction of soybean oil - semantic scholar](/pic/machine-for-press-oil-82.jpg)

[PDF] EVALUATION OF THE PARAMETERS AFFECTING THE SOLVENT EXTRACTION OF SOYBEAN OIL - Semantic Scholar

Soybean is grown primarily for its protein content and secondarily for its oil; it is an excellent protein supplement for enriching cereal diet. The primary processing of soybean before oil extraction include cleaning, cracking, flaking and conditioning, these ruptures the oil cells, for efficient extraction. Most modern oil extraction industries use the solvent extraction process and the

Get Inquiry

(PDF) Optimization of sesame seeds oil extraction operating conditions using the response surface design methodology

This paper applies Response Surface Design (RSD) to model the experimental data obtained from the extraction of sesame seeds oil using n-hexane, chloroform and acetone as solvents under different

Get Inquiry

Optimization of the oil extraction process by response surface methodology from

tion. In the past, solvent extraction was used to extract essential oil from several sources of nuts and seeds, such as Jatropha curcas [9], soybean [10], castor seed [11], coconut [12], and tobacco seed (Nicotiana tabacum L.) [13]. The extraction yield of oiln

Get Inquiry

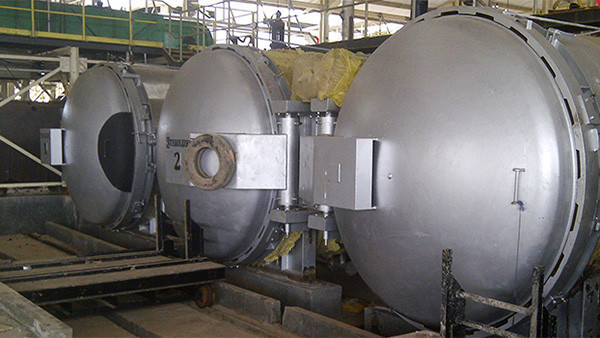

Rotary Extractor Machine - Professional Supplier Of Oil Mill Processing Equipment

The rotary extractor for oil solvent extraction designed by Wintone Machinery has the following advantages: (1) According to the principle of counter current gradient, the material can be extracted fully. (2) Using stainless steel gate, with the simple structure and convenience operation. (3) High material layer, Large diameter and daily output.

Get Inquiry

Soybean oil extraction using ethyl acetate and 1-butanol: From solvent selection to thermodynamic assessment - ScienceDirect

At the end of each extraction, the raffinate and the extract were separated, and the mass of soybean oil extracted was determined gravimetrically after complete evaporation of the solvent. The extractions were made at least in triplicate for the kinetic study and to obtain the maximum yield of soybean oil extraction through Soxhlet.

Get Inquiry

Soybean oil extraction with ethanol from multiple-batch assays to reproduce a continuous, countercurrent, and multistage equipment - ScienceDirect

The batch extraction sequence assumed to experimentally reproduce the 3-stage countercurrent extraction is demonstrated in Fig. 1 a, in which each circle corresponds to an experimental extraction step.Letters S, F, E i ¡¯, and R i ¡¯ represent the pure solvent, raw material, extract, and raffinate streams in stage i, respectively.

Get Inquiry

7,000 growth capital investment into SAMANU, Ethiopia¡¯s largest - Manufacturing Africa

MA-Supported FMCG Company in Ethiopia Secures Investment. ¨C an Africa focused management firm ¨C have made a $21 milliongrowth c. pital investment into SAMANU, Ethiopia¡¯s largest FMCG platform.The investment will fund the construction of a new integrated solvent extraction plant to enable the production of edible oil from locally.

Get Inquiry

Soybean oil extraction and separation using switchable or expanded solvents - Green Chemistry (RSC Publishing)

This article presents a preliminary assessment of several new methods for soy oil extraction and subsequent solvent removal from the oil. The most promising are (a) extraction by an amidine switchable solvent that can then be removed from the soy oil by carbonated water and (b) extraction by a moderately hydrophilic solvent that can then be removed from the oil by water .

Get Inquiry

(PDF) Characterization and Optimization of Soybean Oil from Soybean Seed (Keta and Billo 19) Variety

Then, the request of response surface methodology to optimize oil extraction from soybean seed has been successfully confirmed at optimum parameters: temperature 70, solvent to solid ratio 10

Get Inquiry![[pdf] evaluation of the parameters affecting the solvent extraction of soybean oil - semantic scholar](/pic/machine-for-press-oil-75.jpg)

[PDF] EVALUATION OF THE PARAMETERS AFFECTING THE SOLVENT EXTRACTION OF SOYBEAN OIL - Semantic Scholar

Soybean is grown primarily for its protein content and secondarily for its oil; it is an excellent protein supplement for enriching cereal diet. The primary processing of soybean before oil extraction include cleaning, cracking, flaking and conditioning, these ruptures the oil cells, for efficient extraction. Most modern oil extraction industries use the solvent extraction process and the

Get Inquiry

The Environmental and Social Impact Assessment Report for the proposed Etete Solvent Extraction Plant, Ethiopia - MIGA

ESIA for Proposed Etete Solvent Extraction Plant iv samples were recovered to assist in establishing the existing air quality (H 2 S, NO 2, SO 2, CO 2, CH 4, PM 10, PM 2. 5), noise levels (dB) and soil conditions both inside and outside the site. Water samples

Get Inquiry

Recent advances in green soybean oil extraction: A review

The application of green solvents in soybean oil extraction is reviewed. Hansen parameters and COSMO-based models can serve as a solvent selection tool. Direct substitution of hexane with green solvents is the most promising alternative. Kinetic models and the thermodynamic assessment are analyzed comprehensively.

Get Inquiry

Thermodynamic and statistical analysis of soybean oil extraction process using renewable solvent - Rodrigues - 2010 - International Journal

The main goal of this work was to evaluate thermodynamic parameters of the soybean oil extraction process using ethanol as solvent. The experimental treatments were as follows: aqueous solvents with water contents varying from 0 to 13% (mass basis) and extraction temperature varying from 50 to 100 ¡ãC.

Get Inquiry

Extraction of oil from soybeans - Serrato - 1981 - Journal of the American Oil Chemists' Society - Wiley Online Library

The Journal of the American Oil Chemists' Society publishes original research and technological advances on fats, oils, oilseed proteins, and related materials. Modern processing plants extract soyabean oil by solvent liquid transfer. Soyabeans are cleaned

Get Inquiry