(PDF) Extraction of Residue Oil from Palm Oil Mill Effluent (POME

oil from POME with solvent to POME ratio of 6:10. It was estimated about 0.54 grams of oil. and grease per liter of POME can be extracted at optimum conditions; mixing speed of 200 rpm, 20 minutes

Get Inquiry

Edupalm | The Palm Oil Refining Process

The Palm Oil Refining Process. DIGESTION. The fruits are heated and the exocarp is digested in the digester. Mesocarp is separated from the endocarp and kernel. PRESSING. Mesocarp is pressed to release crude palm oil in the extraction or pressing machine. Kernel is separated from the endocarp before crude palm kernel oil (CPO) is extracted.

Get Inquiry

CRUDE GLYCERINE RECOVERY FROM GLYCEROL RESIDUE WASTE FROM A PALM KERNEL

In the production of palm kernel oil methyl esters, large amounts of glycerol residue are produced from glycerol refining - about 1 t day-1 by a particular plant alone. With the demand for methyl esters and fatty alcohols expected to increase greatly, the amount of glycerol residue generated will also rise.

Get Inquiry

My Say: Using Palm Oil Residue for Fuel and Feed Makes Green Sense

From the palm fruit seed or kernel, palm kernel oil is extracted. Both are useful materials, with palm oil traditionally used for edible purposes such as cooking and frying, whereas palm kernel oil is for non-edible purposes such as the formulation of soap, cosmetics and detergent. The residue that remains ¡ª tonnes of it ¡ª is known as palm

Get Inquiry

Everything You Need to Know About Palm Oil Refinery Process

The refining process of palm oil includes the following: Bleaching. Deodorisation. Fractionation. The crude oil is refined using two methods, including physical refining and chemical refining, during which FFA is removed to ensure that the FFA content is not more than 0.1 %. It is essential to note that physical refining is environment-friendly

Get Inquiry

A Step-by-Step Guide Start a Palm Oil Production Business

The oil extracts from the pulp of the oil palm tree's fruit, which is reddish due to beta-carotene. The fruit is similar to the size of a large olive, contains a single seed, used to make palm kernel oil. Each palm fruit contains about 30-35% oil. Palm oil is the second most produced edible oil globally. Australia imports around 130,000 tons

Get Inquiry

3. PALM OIL PROCESSING - Food and Agriculture Organization

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

Get Inquiry

PFAD residue from palm oil refining | Neste

Palm fatty acid distillate or PFAD is one of the many waste and residue raw materials that we have in our portfolio.. Although linked through supply chains, palm oil and PFAD are different renewable raw materials: palm oil is a crop-based vegetable oil whereas PFAD is a processing residue derived from the refining of food-grade palm oil for the food and chemical industry uses.

Get Inquiry

How is Palm oil refined ¨C Oil Genesis

Before we understand refined palm oil in detail, let us look at how crude palm oil is obtained. The extraction process of palm oil includes the following steps: Harvesting- Once the oil palm fruit is ripe, the clusters are harvested by skilled labor with the help of a sickle or machete. On average, a bunch is close to 25 kilos.

Get Inquiry

PFAD residue from palm oil refining | Neste

Palm fatty acid distillate or PFAD is one of the many waste and residue raw materials that we have in our portfolio.. Although linked through supply chains, palm oil and PFAD are different renewable raw materials: palm oil is a crop-based vegetable oil whereas PFAD is a processing residue derived from the refining of food-grade palm oil for the food and chemical industry uses.

Get Inquiry

By-products of palm oil extraction and refining

Figure 2. Products and by-products from palm oil milling and refining. 5000 ppm), phospholipids (6000 ppm), phe-nolics (1000-2000 ppm) and squalene (1000-1800 ppm) [7-9]. Research by MPOB scientists [9] showed that a single-step supercritical fluid extraction can be effectively used to recover residual oil from PPF.

Get Inquiry

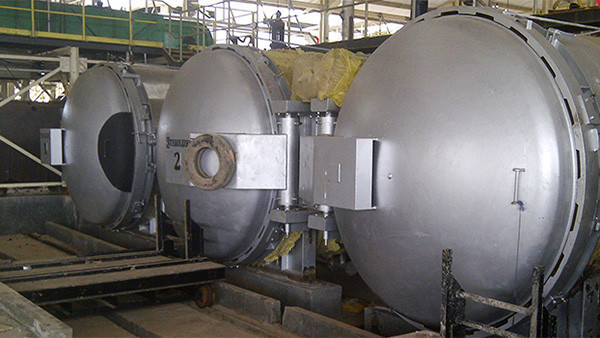

Physical refinery: (a) degumming and bleaching processes; (b

Deodorisation is the key process to produce high©quality refined, bleached and deodorised palm oil (RBDPO) in a palm oil refinery. In this work, an integrated simulation¨Coptimisation approach

Get Inquiry

A Brief Review on Palm Oil Liquid Waste Conversion Into Biofuel

24. Palm oil is an important edible oil due to its high content of beta-carotene and. vitamin E, high oil output, and solid fat content. However, its extensive. commercialization has resulted in a vast amount of waste, leading to challenges. for the development of an economically feasible conversion of palm oil waste.

Get Inquiry

An integrated biorefinery strategy for the utilization of palm-oil

Each hectare of a palm-oil crop emits 50¨C70 tons of biomass waste ( Shuit et al., 2009 ). The waste is made up of OPTs, OPFs, EFBs, mesocarp fruit fiber (MF), PKSs, and POME. Except for POME, all of these wastes are high in fiber. OPFs could be harvested from palm-oil plants year-round due to the practice of pruning.

Get Inquiry

(PDF) Characterization of Empty Fruit Bunch of Palm Oil as Co-firing

characteristics of EFB from the prox imate analysis revealed moisture content of 11.98%, ash content of 6.53%, volatile matter content of 65.15%, and fixed carbon content of. 16.44%. According to

Get Inquiry

(PDF) Preparation of unsaponifiable fraction from crude palm oil: a

Abstract. Crude Palm Oil (CPO) is one of vegetable oil obtained by extracting palm fruit. mesocarp and has a r ed co lor because of t he high content of bet a carotene. Other bioactive

Get Inquiry

PFAD Residue from Palm Oil Refining - Palm Chemicals

Hence, palm oil refining means to boost the output of eatable palm oil, not PFAD. PFAD is, in any case, created despite producers¡¯ ceaseless endeavors to improve their cycles to limit PFAD volumes and boost the output of more significant portions from the refinery. Since PFAD is a non-wanted output of the palm oil refining measure that the

Get Inquiry

Oil Palm Tree Wastes 11: Other by-products from the processing of oil

Plate 4: A heap Palm oil fuel ash (Source: ScieceDirect.com) Palm oil clinkers (POC) POC is another by-product from the combustion of palm oil biomass residue wastes in the mill boiler. When mesocarp fibre, and oil palm shell are combusted, about 5 percent of POFA, and 15 percent of POC are produced, indicating that more POC than POFA is produced.

Get Inquiry

Flow chart of the production chain of palm oil and palm kernel oil

Selecting oil plant varieties with low lipase activity to reduce formation of FFA and acylglycerol precursors. Minimising use of substances such as fertilizers, pesticides, and irrigation water containing chlorine compounds during cultivation. Harvesting oil palm fruit when they are at optimal ripeness.

Get Inquiry