Solvent Extraction

Background One of the most basic needs of mankind is an abundant and reliable food supply. In the modern world, one major source of protein and vegetable oil is from oilseeds, particularly the soybean ¨C an abundant resource which is largely processed using solvent extraction, an efficient and reliable means to separate the high-protein meal solids from the high-energy edible oil.

Get Inquiry

Soybean Oil Processing Business Startup Cost and Project

Oil content of soybean is low, poor plasticity, so it is generally softened before flaking. Flaking temperature should depend on the level of moisture content of soybeans. Soybean moisture for 13% to 15%, softening temperature is usually mastered in 70 ~ 80 degrees, softening time 15 ~ 30 minutes.

Get Inquiry

Soybean Processing - Crown Iron Works

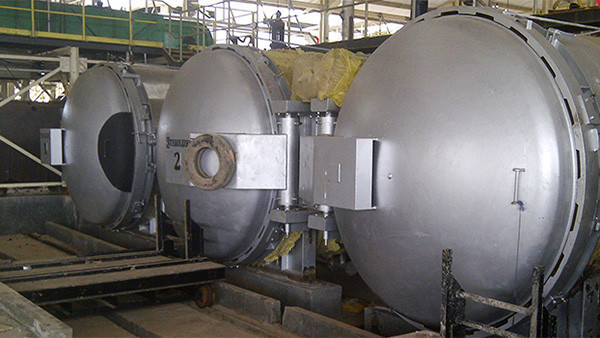

The extraction process uses hexane or other solvents to wash the soybean oil from the prepared soybean flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run the

Get Inquiry

The Ultimate Guide of Soybean Oil Extraction Methods

The standard soybean oil pressing production process includes multiple steps such as cleaning, crushing, softening, embryo rolling, steaming, pressing and filtering. Different types of oilseeds have different pressing production processes. The residual oil rate in the oilseed meal after pressing is generally about 6%.

Get Inquiry

Recent advances in green soybean oil extraction: A review

Soybean oil extraction at the boiling point of p-cymene gave a yield of 31.63 1.50 g/g DM compared to 24.28 1.11 g/g DM for n-hexane. The extraction yield for n-hexane is in line with the

Get Inquiry

Soybean Oil Extraction and Processing - Springer

B. Extraction Theory. Solvent extraction of soybeans is a diffusion process in which the solvent (hexane) selectively dissolves miscible oil components. During extraction, hexane solubi- lizes soy oil from cotyledon lipid bodies in soy flakes rapidly, as soon as it enters the lipid body.

Get Inquiry

Advances in Aqueous Extraction Processing of Soybeans

Aqueous extraction processing technologies, having advanced in recent years, may be a viable alternative to hexane extraction to separate oil and protein from soybeans. Different extraction strategies incorporating various modes of comminution, extraction buffers, and enzymes allow production of a range of oil and protein products, but also

Get Inquiry

Solvent Extraction Plant (soybean oil processing) - YouTube

It is a continuous process flow of Soybeans oil processing, to whom in #oils & fats industry #agriculture #plantationIncluding:Preparation WorkshopSolvent Ex...

Get Inquiry

9.11.1 Vegetable Oil Processing - U.S. Environmental

9.11.1 Vegetable Oil Processing 9.11.1.1 General1-5 The industry group producing fats and oils includes cottonseed oil mills, soybean oil mills, vegetable oil mills (other than corn, cottonseed, and soybean), and other mills. Wet corn mills are the primary producers of corn oil. Approximately 137 vegetable oil plants operate in the United States.

Get Inquiry

Recent advances in green soybean oil extraction: A review

According to USDA [1], the production of soybeans worldwide in 2020/2021 was about 360,000 thousand metric tons. The soybean seeds are mainly destined for protein, edible oil, and biodiesel production. The main components of the seeds are proteins (40 wt%), lipids (20 wt%), carbohydrates (15 wt%), and ashes (5 wt%).

Get Inquiry

Soybean oil extraction with ethanol from multiple-batch assays to reproduce a continuous, countercurrent, and multistage equipment - ScienceDirect

The batch extraction sequence assumed to experimentally reproduce the 3-stage countercurrent extraction is demonstrated in Fig. 1 a, in which each circle corresponds to an experimental extraction step.Letters S, F, E i ¡¯, and R i ¡¯ represent the pure solvent, raw material, extract, and raffinate streams in stage i, respectively.

Get Inquiry

Soybean Oil Extraction and Processing - SpringerLink

Soybeans are the dominant oilseed in both U.S. and world markets. During a typical year soybean production comprises over half the worldwide oilseed production ( Anonymous 1995 ). However, according to Dutton (1981) in the early 1940s, soybean oil was considered a poor quality oil, not suitable for food use, and more appropriate for use in

Get Inquiry

Whole soybean protein extraction processes: A review

The aqueous extract of whole soybean extraction is called soybase and it is mainly used for making consumer products containing both soy protein and soybean oil. Products like soymilk, soy-fruit beverages and tofu are produced by adding various ingredients to the soybase, such as flavours, gums, stabilisers, minerals, vitamins, sugars, fruit juices and/or coagulating agents in case of tofu.

Get Inquiry

(PDF) Mass transfer in soybean oil extraction using ethanol/isopropyl alcohol mixtures

This hypothesis is adopted by several authors to describe diffusive process (e.g., [27¨C29]); (3) No equilibrium relation is used to relate the oil phase inside the solid matrix with the concentration in the porous, instead, mass balance is done considering the total

Get Inquiry

Prospects of Edible Oil and Soybean Crush Industry in Bangladesh

As such, the soy crush then caters to 2 different markets: oil and feed. A closer look at the soybean crushing process shows that it consists of 3 major steps: cleaning and dehulling soybean seeds, solvent extraction, and meal treatment. Primarily, the seeds are dehulled and the hulls are heated and ground to produce low (42 to 43 percent

Get Inquiry

Bioactive Phytochemicals from Soybean Glycine max) Oil Processing By-products

Soybean meal is a by-product of the oil extraction process of soybean oilseeds. Soybean meal is generally utilized in animal diets, particularly poultry diets, due to its high nutrition values, protein quality, excellent amino acid prole, and high. fi. amino acid digestibility [4].

Get Inquiry

Soybean oil extraction with ethanol from multiple-batch assays to reproduce a continuous, countercurrent, and multistage equipment

To obtain soybean oil in a simulated moving bed extractor, at 60 ? C, Ferreira et al. (2022) compared the minimum solvent flow rate (S min ) values in continuous countercurrent extractors for

Get Inquiry

Extraction of oil from soybeans - Serrato - 1981 - Journal of the American Oil Chemists' Society - Wiley Online Library

Modern processing plants extract soyabean oil by solvent liquid transfer. Soyabeans are cleaned, cracked, dehulled and conditioned into a thin flake before they enter the extractor. Extraction is by successive, countercurrent washes of hexane solvent.

Get Inquiry

Soybean Oil Extraction and Processing

B. Extraction Theory. Solvent extraction of soybeans is a diffusion process in which the solvent (hexane) selectively dissolves miscible oil components. During extraction, hexane solubi- lizes soy oil from cotyledon lipid bodies in soy flakes rapidly, as soon as it enters the lipid body.

Get Inquiry