Waste Tyre to Oil Plant - Kingtiger

Kingtiger is the top professional manufacturer of tyre to oil plant in China; our company has researched a suit of high-tech pyrolysis plant, which can convert waste tyre to oil in large scale, in principle of green, sustainable development and economic benefits. This plant has a great market potential. And it is also can turn waste plastic to oil.

Get Inquiry

Tyre to Oil Plant -?? Turn Scrap Tyre into Wealth - Beston Group

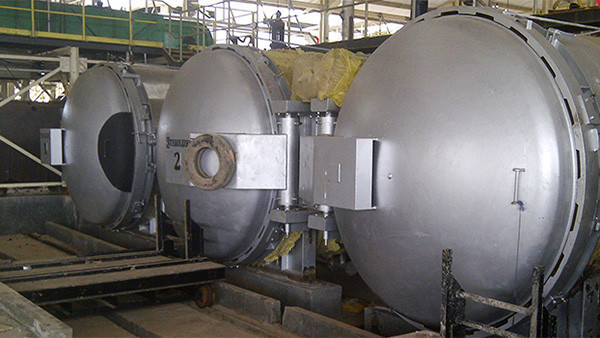

Tyre to oil plant, also known as tyre pyrolysis plant, is an environmentally friendly equipment. Generally, this kind of machine aims to convert scrap tyres into useful resources such as pyrolysis oil, carbon black, and steel wire. Additionally, the plant uses a pyrolysis process that involves heating the tyres in a low-oxygen, micro-pressure

Get Inquiry

Waste tyre/tire to fuel oil pyrolysis plant

The waste tyre/tire to fuel oil pyrolysis plant manufactured by Doing group can be used for recycling tyre/tire into fuel oil, carbon black and steel wire. 09-22-2016 17:52:10 +86-135-2669-2320

Get Inquiry

How to start a scrap tire pyrolysis plant in Germany?

The scrap tire pyrolysis plant mainly consists of automatic feeder, pyrolysis reactor, condenser, oil tank, oil-water separator, slag discharge device, environmental protection system, etc. You can also choose the right configuration according to your actual situation. In addition, there are two main types of scrap tire pyrolysis plant in the

Get Inquiry

Scrap tire derived fuel pyrolysis plant

1.Using Scrap tire derived fuel pyrolysis plant available for sale, stick to experience an excellent, eco-friendly & cost-effective solution for tyre recycling. 2.On an average, the entire pyrolysis process may lead to a yield of around 45-52% oil, 30-35% charcoal, and 15% gas. The oil produced is mainly made up of diesel, kerosene, benzene

Get Inquiry

Thermochemical recycling of mixture of scrap tyres and waste

Tire pyrolytic oil (TPO) has been reported to be similar to commercial diesel fuel. The current hurdle for using TPO in commercial diesel engines is the available sulfur content (>1.0 wt%).

Get Inquiry

Oil and Aromatic Yield Maximization During Pyrolysis of Scrap Tire

Here, we report the optimization of scrap tire rubber (STR) pyrolysis in a fixed-bed reactor for the production of pyrolytic oil (py-oil). Special attention was focused on determining the effects of the temperature and gas residence time on the py-oil and aromatic yields, as well as the optimal range of operating conditions for their maximization. For that purpose, an experimental 4 ¡Á 3

Get Inquiry

Production of Oil and Char by Intermediate Pyrolysis of Scrap Tyres

Oil (a) and char (b) yields as a function of temperature and reaction time using 1.9 mm size particle for scrap tyres, Q g ? 200 NmL/min. ¡

Get Inquiry

Waste Tyre Oil Plant - Affordable Tire to Fuel Machine Cost

End Products of Waste Tyre Oil Plant. Obviously, you can make oil from scrap tires. The oil yield rate is about 45%, which is influenced by many factors, for example, the water content of raw material. Except for fuel oil, you can also get 30% to 35% of carbon black, 8% to 15% of steel wire and combustible gas.

Get Inquiry

How to Convert Scrap Tires into Biofuel - EcoMENA

Conversion of old tires into biofuel. There are two physical actions involved in the conversion of tires into biofuel: shredding and pyrolysis, or the decomposition of the tires by exposing it at high temperatures and the use of a special catalyst. TDF processing may involve whole tires or tires cut down into uniform species.

Get Inquiry

Scrap Tyre Management Pathways and Their Use as a Fuel¡ªA Review

This article provides a review of different methods for managing waste tyres. Around 1.5 billion scrap tyres make their way into the environmental cycle each year, so there is an extreme demand to manage and mitigate the environmental impact which occurs from landfilling and burning. Numerous approaches are targeted to recycle and reuse the tyre rubber in various applications. Among them, one

Get Inquiry

Pyrolysis Plant Manufacturer & Gasification Equipment Supplier

April 25, 2024 Klean Industries & L4T Group Life for Tyres Sign MOU to Accelerate the Deployment of Advanced Manufacturing Facilities; April 22, 2024 Tire Technology International - Features Klean Industries & Reoil; April 17, 2024 Klean and Reoil Expand their Relationship Collaborating on Klean Loop to Solve the End-of-Life Tyre Crisis

Get Inquiry

Tire to Oil Plant - Fair Tyre to Fuel Machine Cost - Beston

The higher the oil rate and oil quality, the more the benefits you can get. It will get your tyre recycling plant cost back soon. The oil yield rate of Beston tyre pyrolysis plant can reach up to 45%. It means you can get about 45o kg of tyre pyrolysis oil for 1000 kg of old tyres.

Get Inquiry

Understanding The Tire Pyrolysis Plant: A Comprehensive Guide To

In summary, tire pyrolysis plants offer an effective method for recycling scrap tires and converting them into alternative energy sources without polluting the environment. To prevent air and water pollution, it is crucial to ensure that your waste tire pyrolysis facility incorporates a comprehensive set of systems such as smoke cleaning, tail gas cleaning, odor elimination, and water circulation.

Get Inquiry

Old Process Aims To Convert Tires into New Oil - Waste360

According to a Tires2Oil report, the system will produce 476,300 tons of carbon black, or 333,400 tons of activated carbon, and 5.5 million barrels of oil annually from 270 million scrap tires

Get Inquiry

Scrap Tyre Pyrolysis Plant & Tire Recycling Equipment - Klean Industries

Stay Up To Date. Tyre pyrolysis plant with five types turns waste tires into diesel oil and recovered carbon black. Best technologies and fair costs that deliver customers benefits.

Get Inquiry

An economic analysis of scrap tire pyrolysis, potential and new

The purpose of this study was to evaluate the economic potential of scrap tire pyrolysis at the macro level and to determine the financial contribution of the emerging pyrolysis industry to the overall economy. The paper is organized as follows. Section 2 presents terminology and the status of the tire recycling industry.

Get Inquiry

(PDF) Waste Tires Pyrolysis Oil as a source of energy

1.1. Energy recovery. One of the main ways to recycling used tires o r other waste rubber products is to use. them as a fuel and is referred to as Tire-Derived Fuel (TDF). Used tires have a

Get Inquiry

Tire Pyrolysis Produces Recovered Carbon Black & Marine Fuel - Klean

Klean's planned Resource Recovery Facility will not require any subsidies and will provide a fully sustainable solution to the region's +5m scrap tires. Klean's solution will solve part of the scrap tire issue by using the company's patented advanced thermal conversion technology to recover fuel oil, steel, and refined carbon black.

Get Inquiry