Hydrothermal Carbonisation of Empty Palm Oil Fruit Bunches: Laboratory

Empty fruit bunches (EFB) from the production of palm oil constitute a significant and increasingly problematic waste stream. Direct firing is hindered by a water content of 65 %. This paper investigates hydrothermal carbonisation (HTC) as one method of upgrading EFB waste to an exportable fuel. We first undertook bench experiments using EFB from Sumatra, Indonesia. The reactor was operated at

Get Inquiry

Integrated Biorefinery of Empty Fruit Bunch from Palm Oil ...

Empty fruit bunch (EFB) utilization to produce valuable bio-chemicals is seen as an economical and sustainable alternative to waste management in palm oil industries. This work proposed an integrated biorefinery configuration of EFB valorization considering sustainability pillars¡ªnamely, economic, environmental, and safety criteria. Techno-economic analysis, life cycle assessment, and hazard

Get Inquiry

(PDF) Optical properties of oil palm Fresh Fruits Bunch (FFB)

When ha rvested. on prime and optimum ripe, the FFB can yield 25-28% of oil extracti on rate (OER), m uch higher. than the current 18-20% nation-wide OER. Whil e the FFB is commonly harvest

Get Inquiry

Supply chain analysis, delivered cost, and life cycle assessment of oil

The CPO extraction process, combustion of EFB, fiber and shells for CHP, and palm oil mill effluent (POME) treatment are not included in the system boundary because these processes are solely attributable to the CPO co-product. Fig. 2. Life cycle stages and major inputs and outputs for the palm oil FFB and EFB production and delivery systems

Get Inquiry

Contents and Utilization of Palm Oil Fruit Waste - Biointerface Research

3.1. Contents of palm oil waste 3.1.1. Palm oil mill effluent (POME) POME is liquid waste from the palm oil production process. Typically, POME is produced from plant operations at temperatures between 80¡ãC and 90¡ãC. The characteristics of POME depend on the quality of the raw material and the oil production process in palm oil Fresh Fruit Bunch

Get Inquiry

A study of palm oil mill processing and environmental assessment

Abstract. This work discusses the palm oil mill processing carried out at Jugra Palm Oil Mill Sdn Bhd, situated at Selangor, Malaysia with the capacity of 45-t fresh fruit bunch (FFB)/h. Typically, oil palm residues and palm oil mill effluent (POME) from FFB are generated while processing. Prior to discharge, POME should be treated to remove

Get Inquiry

Milling process. FFB: Oil palm Fresh Fruit Bunch; RE

Palm oil production involves unit operations that lead to greenhouse gas emissions. A typical mill is estimated to produce greenhouse gas emissions of 637¨C1,131 kg CO2 eq/t crude palm oil.

Get Inquiry

Annotated Datasets of Oil Palm Fruit Bunch Piles for Ripeness ... - Nature

Many studies related to the detection of oil palm fruit ripeness have been carried out, either with a computer vision approach 2,3,4,5,6,7,8,9,10,11,12 or with a light sensor approach 13,14,15,16

Get Inquiry

The design of fresh fruit bunch palm oil purchase system

Palm oil has become a leading vegetable oil over the past 30 years and smallholder farmers in Indonesia, with more than 12 million hectare the world's largest producer of palm oil, have massively

Get Inquiry

Oil Palm Plantation & Milling - Wilmar International

As the oil palm continues to mature, its yield increases and reaches peak production in years seven to 18 before gradually decreasing thereafter. The typical commercial lifespan of an oil palm is approximately 25 years. Fully mature oil palms produce 18 to 30 metric tonnes of fresh fruit bunches (FFB) per hectare.

Get Inquiry

Palm Oil

Introduction. Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, whereby a mill commonly handles 60 to 100 mt per hour of FFB. The palm oil mill of today is based predominantly on concepts developed in the early 1950s (Mongana Report). An average size FFB weighs about 20-30 kg and contains 1500-2000 fruits ( Fig. 1 ).

Get Inquiry

FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB. The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted. A palm oil mill produces crude palm oil and kernels as primary

Get Inquiry

Datasheet ¨C Fresh fruit bunches (FFB) ¨C PALM OIL ENGINEERING

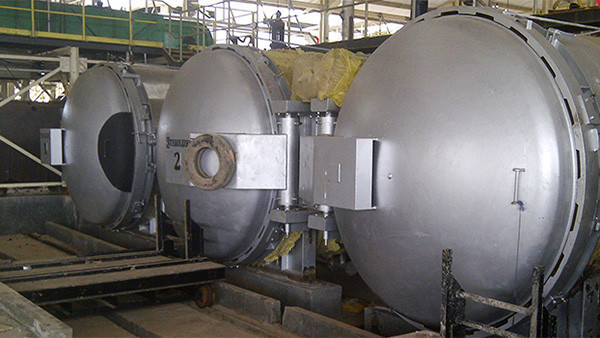

Datasheet ¨C Fresh fruit bunches (FFB) -. FRESH FRUIT BUNCHES (FFB) , CONDITIONS &, CHARACTERISTICS , DATASHEET. Tags: DATASHEET, FRESH FRUIT BUNCHES (FFB), CONDITIONS & CHARACTERISTICS. Author information: Download Full Issue. Continuous sterilization of fresh fruit bunches ¨C part 3.

Get Inquiry

Oil Palm Plantation & Mill - home

Our operations include development of oil palm plantation, oil palm cultivation, management of plantations and milling of fresh fruit bunches (FFB). Malbumi Group's oil palm plantations are privately-owned and located in the state of Sabah. We have been in the business for more than 30 years specialising in oil palm cultivation.

Get Inquiry

Alfa Laval PANX range of decanters for crude palm oil

oil for maximum oil recovery with minimum oil losses.The PANX range therefore includes decanters suitable for every size of palm oil mill, from 30 to approximately 90 tons of fresh fruit bunches (FFB) per hour, and for a variety of crude palm oil applications. These include: ? Combined clarification and purification of pressed oil as

Get Inquiry

A study of palm oil mill processing and environmental

Abstract. This work discusses the palm oil mill processing carried out at Jugra Palm Oil Mill Sdn Bhd, situated at Selangor, Malaysia with the capacity of 45-t fresh fruit bunch (FFB)/h. Typically, oil palm residues and palm oil mill effluent (POME) from FFB are generated while processing. Prior to discharge, POME should be treated to remove

Get Inquiry

Milling process. FFB: Oil palm Fresh Fruit Bunch; RE

Palm oil production involves unit operations that lead to greenhouse gas emissions. A typical mill is estimated to produce greenhouse gas emissions of 637¨C1,131 kg CO2 eq/t crude palm oil.

Get Inquiry

Improving Fresh Fruit Bunches Unloading Process at Palm Oil

The production costs of crude palm oil (ACP) is currently experiencing harvesting, transportation of fresh fruit bunches (FBB) and oil extraction with a participation of 16%, 5% and 21%, respectively . Even though 5% may seem insignificant, these transportation costs are relevant to compete in an international market with countries like

Get Inquiry

shows palm oil plantation production system (FFB: Fresh fruit

Utilization of waste from the palm oil industry (such as empty fruit bunches, mesocarp fiber, and palm kernel shell) as a source of biomass energy is expected to be one of the efforts to increase

Get Inquiry