Cost on Setup Palm Oil Processing Mill in Nigeria

A complete palm oil processing mill plant with a capacity of 50 ton/day is about $ 60,0000, while a full complete palm kernel oil production line with capacity of 10 ton/day is $ 60,000 around. Note: The exact cost of starting a palm oil milling business in Nigeria depends on the capacity requirments, process design and equipment configuration.

Get Inquiry

Palm Oil - Our World in Data

Palm oil production has increased rapidly since the 1960s. Between 1970 and 2020, the worlds production of palm oil increased by about 40 times. Global production went from only 2 million tonnes to around 80 million tonnes. The change in global production is shown in the chart.3.

Get Inquiry

How much does it cost to set up a palm oil production plant

The cost of setting up a palm oil production plant in India is affected by many factors, the approximate cost range is $5000,0-$5,000,000. The most critical influencing factor is what kind of palm oil extraction equipment to purchase.

Get Inquiry

How To Start A Profitable Palm Oil Business in Nigeria (2024)

Requirements To Start A Palm Oil Business in Nigeria. Heres a breakdown of the essential requirements to start a palm oil business in Nigeria: 1. Land and Location. Palm trees require well-drained, fertile soil with a pH range of 6.0 to 8.0. Adequate rainfall or irrigation is crucial for optimal growth.

Get Inquiry

Step-by-Step Guide to Set Up a Palm Oil Mill Plant

Investing in a palm oil mill plant can diversify investment portfolios and secure long-term financial stability. Typical Steps to Setup A Sucessful Palm Oil Milling Plant. 3D FLow of Palm Oil Processing Factory Setup . Setting up a palm oil mill plant involves a series of carefully planned steps to ensure a smooth and successful operation.

Get Inquiry

3. PALM OIL PROCESSING - Food and Agriculture Organization

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

Get Inquiry

This Is How Palm Oil Is Made - Treehugger

This plant produces 60,000 tons of crude oil each year: 45,000 tons are refined on the premises to sell both domestically and internationally, and 15,000 tons are left as crude oil and sold to

Get Inquiry

COST OF SETTING UP A PALM OIL MILL IN NIGERIA

In 2010, Nigeria recorded the highest growth in oil palm, which led to an increase in palm oil production. Over the years, from 2010 to 2021, the palm oil production level of Nigeria has greatly risen to more than 1,200 000 metric tonnes as of 2021, making Nigeria one of the leading countries in palm oil production in the world.

Get Inquiry

How much does it cost to set up a palm oil mill?_FAQ

The cost varies with capacities. 2.Machine material. About same capacity palm oil mill plant, we can use different material to manufacture, carbon steel and stainless steel are common. The cost of carbon steel is lower than that of stainless steel. 3.Processing technology, for same capacity palm oil mill plant, we can offer different types

Get Inquiry

9 Palm Oil Processing Startup Costs to Budget

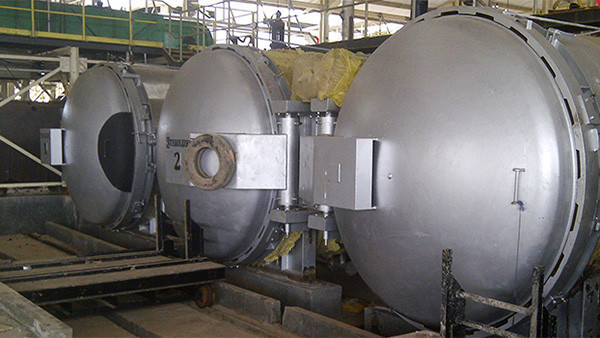

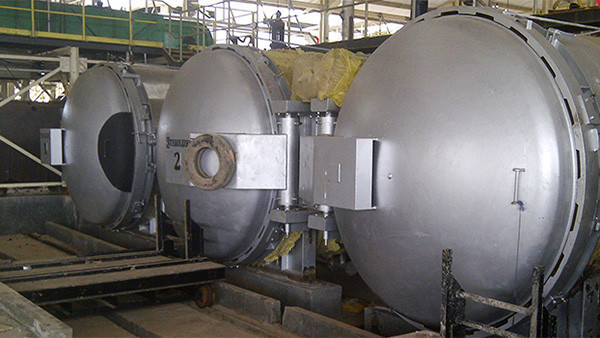

According to recent statistical information, the average cost for machinery and equipment for a palm oil processing facility ranges from $200,000 to $500,000 USD. Palm oil processing plants require several machines for various processes, including sterilizing, threshing, digesting, pressing, and filtering.

Get Inquiry

Palm Oil Processing Plant Report 2024: Setup and Cost - IMARC Group

IMARC Groups report titled ¡ùPalm Oil Processing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue¡ì provides a complete roadmap for setting up a palm oil processing plant. It covers a comprehensive market overview to micro-level information such as unit operations

Get Inquiry

11 Startup Expenses to Launch a Palm Oil Production Business

Installation and set-up cost: $100,000 to $250,000 USD. Maintenance and repair cost: $50,000 to $100,000 USD. Compliance regulations cost: $50,000 to $100,000 USD. In conclusion, the cost of purchasing equipment and machinery for processing is a significant investment for any palm oil production venture.

Get Inquiry

Understanding Palm Oil Processing Plant Cost

Setting Up Cost of Complete Palm Oil Mill: When it comes to to the complete palm oil processing plant cost, the total equipment price is greatly affected by production output and process design. The equipment price is around $20,000~$30,000 for establishing a 5~10 ton/d small palm fruit oil milling factory. About $60,000 is needed as equipment

Get Inquiry

9 Startup Costs to Start a Palm Oil Plantation Business

According to latest statistics, the cost of RSPO certification for a small palm oil plantation (less than 500 hectares) ranges from $3,000 to $5,000, while a medium-sized plantation (500-5,000 hectares) can cost between $10,000 and $20,000. For a large plantation (over 5,000 hectares), the cost can exceed $50,000.

Get Inquiry

Step-by-Step Guide to Set Up a Palm Oil Mill Plant

Operational readiness: Prepare the plant for full-scale operations by establishing standard operating procedures, quality control protocols, and safety measures. By following these general steps, one can establish a well-designed and properly equipped palm oil mill plant that is poised for efficient production and long-term success.

Get Inquiry

A Step-by-Step Guide Start a Palm Oil Production Business

Dive into each step, from extraction to purification, for a clear understanding of Starting a Business in Palm Oil Manufacturing. Discover essential steps to launch a successful palm oil production business. From understanding market trends to setting up processing units, get insights and tips on starting a lucrative palm oil venture.

Get Inquiry

Palm Oil Production Business: A Profitable Investment Opportunity

Palm oil is a crucial ingredient in many of the products we use daily, from food to cosmetics. The palm oil industry has a bright future, with a projected compound annual growth rate of 5.3% from 2021 to 2026. Investing in a palm oil production business can yield high returns, with an average profit margin of 30%.

Get Inquiry

Palm Oil - Our World in Data

Palm oil production has increased rapidly since the 1960s. Between 1970 and 2020, the worlds production of palm oil increased by about 40 times. Global production went from only 2 million tonnes to around 80 million tonnes. The change in global production is shown in the chart.3.

Get Inquiry

Investment Breakdown: Unveiling the True Cost of Oil Mill Plants

Estimated Cost per Ton ($) Peanut Oil. $800. Palm Oil. $900. Sunflower Seed Oil. $700. Please note that these amounts are for illustrative purposes only and may not reflect the actual current market prices. It's essential to consult the latest data and conduct a thorough cost analysis for accurate estimations.

Get Inquiry