Use of pyrolytic gas from waste tire as a fuel: A review

Conclusions. Waste tires should not be treated as typical waste, because they are a rich source of energy (heating value up to 40 MJ/kg) and chemicals, which both can be recovered. Waste tires used in pyrolysis processes can deliver pyrolysis oil, char, calorific gases, process heat and electricity.

Get Inquiry

Study on waste tire pyrolysis product characteristics based on machine learning - ScienceDirect

Abstract. Tire pyrolysis is a highly complex thermochemical conversion process that transforms waste tires into high-value products such as pyrolysis oil, pyrolysis gas, and pyrolysis char. This process significantly mitigates the environmental issues caused by waste tires and reduces reliance on fossil resources.

Get Inquiry

Oil extraction & Gas Absorption from Waste Tyre

Oil extraction & Gas Absorption from Waste Tyre. March 2023. DOI: 10.55041/IJSREM17935. Authors: Patel Ravi Atulbhai. Patel Dev Harshadbhai. Mr.Ritul Bhatt. To read the full-text of this research

Get Inquiry

How Much Oil is Needed to Make One Car Tire? - TireMart.com Tire Blog

Brands make most tires using synthetic rubber. On average, to produce one tire, the process uses seven gallons of oil. Tires are not directly and solely made of oil, it is an essential ingredient for synthetic rubber. Even when using natural rubber, tire manufacturing needs oil later in the process.

Get Inquiry

(PDF) Fractional Distillation & Characterization of Tire Derived Pyrolysis Oil

The liquid fuel is directly used in the engines and that phase is a mixture of complex hydrocarbon. ... tire oil Upgrading fractionated oil C Conventional Diesel Fuel 40-70 71-120 121-180 181-190

Get Inquiry

Tyre Pyrolysis Oil - Uses/ Price/ Specifications - Beston Group

Tyre pyrolysis oil, abbreviated as TPO, is the target product of waste tyre pyrolysis. It is a product obtained by condensing the oil gas decomposed by the high-temperature process. The oil is widely used as industrial fuel to substitute furnace oil or industrial diesel. It can be also called tire pyrolysis oil, crude TPO, tire pyrolytic oil, etc.

Get Inquiry

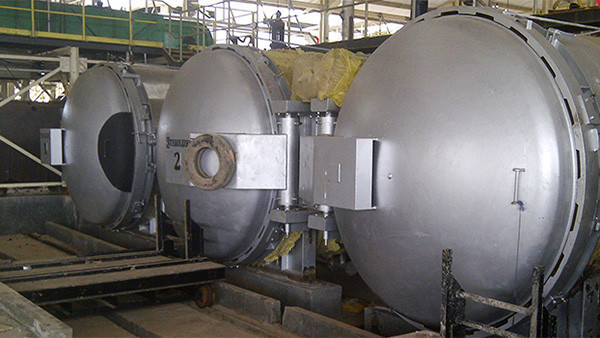

Two sets 12T/D waste tire oil extraction machine installed in Sichuan, China

This time, he signed the contract of 2 sets 12T/D waste tire oil extraction machines directly, and paid the deposit on the spot. The tire oil coming out from the tire oil extraction machine Now the waste tire oil extraction machines run well and produce tire oil smoothly.

Get Inquiry

Tyre to Oil Plant - Quote from Manufacturer in 24-hours - Beston Group

Tyre to Oil Plant. Beston tyre to oil plant aims at turning waste tyre to high-valued oil. Through advanced pyrolysis technology, this kind of machines can process 1-24 tons of tyre. Besides, we can get by-products (carbon black and steel wire). Under the sealed high-temperature process, waste tyre can be turned into oil in 4-8 hours.

Get Inquiry

How to Convert Scrap Tires into Biofuel - EcoMENA

Conversion of old tires into biofuel. There are two physical actions involved in the conversion of tires into biofuel: shredding and pyrolysis, or the decomposition of the tires by exposing it at high temperatures and the use of a special catalyst. TDF processing may involve whole tires or tires cut down into uniform species.

Get Inquiry

Fuel from Old, Unused Tires? Heres How its Being Done

Pyrolysis is an extremely interesting alternative when it comes to recycling tire materials to produce alternative fuels and high value-added petrochemicals. In detail, pyrolysis is the thermal decomposition of organic and many inorganic compounds. In the narrow sense the decomposition of organic natural compounds with a lack of oxygen.

Get Inquiry

How to extract crude oil from used tyres by used tyre pyrolysis equipment?

After preheating for about 2 hours, the tyres will become into oil gas, and the oil gas will enter the cooling area through the oil gas outlet pipe, and the oil gas will be cooled into crude oil. Last, the crude oil will flow into the storage tank. The water is circulated in this process, so there is no polluted water at all.

Get Inquiry

How to Convert Scrap Tires into Biofuel - EcoMENA

Shredders are high-shear and low-torque in nature capable of reducing truck tires with an outside diameter of 48 inches to 1 to 4-inch pieces. After the tires have been cut into smaller pieces, these are then fed into a pyrolysis reactor. In this machine, the rubber is softened by exposing it to high temperatures that can exceed 700 degrees

Get Inquiry

Waste Tyre Oil Extraction Machine - Extracting Oil from Tires

Get Free Quote in 24 Hours. Kingtiger waste tyre oil extraction machine can turn waste plastic, waste rubber and waste tires into high-quality tire oil, carbon black and steel wire. As a leading pyrolysis machine manufacturer, Kingtiger Group has 20 years experience in waste disposal, and we can give the customized solution to meet our

Get Inquiry

Catalytic cracking of scrap tire-generated fuel oil from pyrolysis

Upgraded scrap tire-generated fuel oil using zeolite ZSM-5 can be suggested as an alternative source of energy that could make a clean environment. On the other hand, the utilisation of scrap tire can fulfill the goals of sustainable waste tire management and reduce environmental degradation in developing countries like Bangladesh.

Get Inquiry

End-of-life tyre conversion to energy: A review on pyrolysis and

This reactor is commonly used in the chemical and oil industry as it can produce high-quality liquid fuel, and the yield of pyrolysis oil through the reactor is 60-70 % wt. Numerous studies found that the partial size of the tyre has a significant impact on the efficiency of the reactor, and the particle size should be not >3 mm (Kaminsky and Mennerich, 2001; Kaminsky et al., 2009).

Get Inquiry

A Review on the Thermochemical Recycling of Waste Tyres to Oil

Utilising pyrolysis as a waste tyre processing technology has various economic and social advantages, along with the fact that it is an effective conversion method. Despite extensive research and a notable likelihood of success, this technology has not yet seen implementation in industrial and commercial settings. In this review, over 100 recent publications are reviewed and summarised to give

Get Inquiry

Recycling waste vehicle tyres into crumb rubber and the transition

Tyre Stewardship Australia (TSA) reports a higher amount of 17% (27,000 tons) truck tyres recycled due to the presence of more natural rubber than passenger car tyres. Recycling of associated by-products steel and textile has been calculated by adopting the grant model as shown in Equation 1 ( Grant, 1999 ).

Get Inquiry

Production of pyrolysis oil from used tyres and the effects

The treated oil was distilled, and the products obtained have properties similar to gasoline and diesel fuels. The light tyre pyrolysis oil (LTPO) was blended with regular gasoline and the various blends obtained were used in powering an electric generator, and the fuel consumption rate in the generator was observed to reduce with an increase

Get Inquiry

Waste tire pyrolysis and desulfurization of tire pyrolytic oil (TPO

Tire pyrolytic oil (TPO) has been reported to be similar to commercial diesel fuel. The current hurdle for using TPO in commercial diesel engines is the available sulfur content (>1.0 wt%). The disadvantages of sulfur in liquid fuels are its ability to reduce the engines life due to corrosion and the undesirable emission of SO x that subsequently damages public health and property.

Get Inquiry