Dewaxing / Winterization/Palm Oil Dry Fractionation

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0¡Í to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Get Inquiry

Dewaxing - SpringerLink

In Europe, the removal of wax from oils such as sunflower seed oil or corn germ oil is commonly referred to as ¡ùwinterization.¡ì However, when I used this term in the US, people thought I was referring to a process to remove higher-melting triglycerides from an oil such as cottonseed oil or brush hydrogenated soybean oil, a process that is called ¡ùdry fractionation¡ì in Europe.

Get Inquiry

Supply palm oil fractionation plant, cooking oil winterization or

If you wanna to get more details about Oil fractionation and dewaxing process you can send E-mail to [email protected]. You can consult our professional engineer and specialized sales team with leave a message in below form.We will contact with you ASAP.You also can visit our factory in Henan,China.

Get Inquiry

Dewaxing, Degreasing, Winterization fractionation technology - Food oil

Palm oil fractionation technology is a new oil processing technology. Using palm oil fractionation technology can get80C, 1009C, 140¡Í, 180C, 2400, 330c, 440c, 550c, etc, different melting points palm oil products. At the same time, it can also be used to process cottonseed oil, fish oil, pork oil, and other animal oils.

Get Inquiry

Supply palm oil fractionation plant, cooking oil winterization or

If you wanna to get more details about Oil fractionation and dewaxing process you can send E-mail to [email protected]. You can consult our professional engineer and specialized sales team with leave a message in below form.We will contact with you ASAP.You also can visit our factory in Henan,China.

Get Inquiry

Rice Bran Oil Winterizing Equipment - dsoilpress.com

Rice bran oil has a high solid fat content, which contains 1%-3.8% stearic acid and 12%-18% palmitic acid. The solid fat crystallizes at low temperature, the fat becomes muddy, and solid-liquid stratification occurs. After the rice bran oil is physically refined, the acid value KOH is 1-3 mg/g, cooled to 30¡«C, pumped into the crystallization

Get Inquiry

Edible Oil De-waxing & Winterization - Kumar Metal Industries

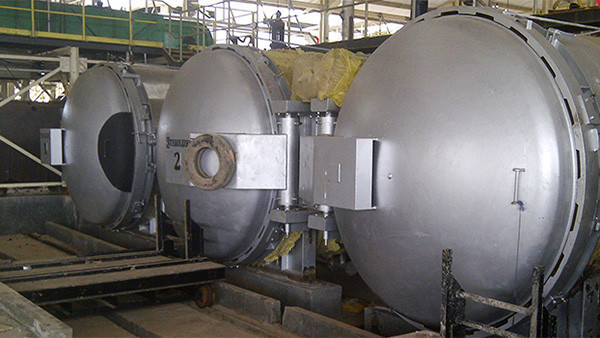

The dewaxing or winterization process involves the cooling of oil to crystallize high melting compounds followed by filtration or centrifugation to separate crystallized mass from oils. Bleached or deodorized oil is first cooled through a series of heat exchangers and then fed to the crystallizers. Crystallizers are equipped with double-layered

Get Inquiry

Winterization/fractionation/dewaxing_Winterization machine

Palm oil fractionation plant can process palm oil and palm kernel oil.Winterization dewaxing machine can process rice bran oil,sunflower oil,corn germ oil.oil fractionation Winterization dewaxing machine manufacturer.

Get Inquiry

Enhanced Winterization,Oil Dewaxing - Oil Mill Plant

The wax content od oil depends on the oil content of oil seeds and the process technology. Generally speaking, for sunflower seeds with an oil comtent of at least 40%, the wax content is 0.65-2.33%, when processing decorticated seed. A good winterization process should also be able to dewax oil from undecorization of dcacidification.

Get Inquiry

Oil Dewaxing Winterization,Fractionation - Oil mill

It is almost necessary to dewax the following products (such as corn oil, rice bran oil, sunflower oil, cottonseed oil, etc.). Oil fractionation is done by using the differences in glycerols melting point and solubility contained in various oils to divide the oil into solid fats and liquid oils. In theory, oil dewaxing (winterization) and

Get Inquiry

Oil Winterization, Fractionation, Dewaxing Machinery for Oil

Conventional dewaxing is the simplest oil crystallization and filtration method. First of all, the oil crystallization is carried out in the cooling chamber at 0~4¡Í, after 72 hours cooling, the final oil temperature in oil tank is around 6~10¡Í. The average cooling rate is 2¡Í/hour at the first 24 hours of cooling period, the cooling

Get Inquiry

Winterization/fractionation/dewaxing-Winterization machine

Theoretically, winterization/dewaxing is different from fractionation. However, they have the same technical process, same with the equipments needed. Different oils need different process to get better quality. Our engineer can help you choose most suitable line according to your raw material and requirements.

Get Inquiry

Dewaxing / Winterization/Palm Oil Dry Fractionation

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0¡Í to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Get Inquiry

Introduction of Winterization/fractionation/dewaxing - LinkedIn

Winterization/dewaxing Waxiness impacts palatability of oil; winterization/dewaxing focus on increasing palatability of oil and impoving organoleptic properties such as transparency, brightness

Get Inquiry

Palm Oil Fractionation Equipment - dsoilpress.com

Palm oil fractionation is an important process of palm oil refining plant. This new type of palm oil fractionation equipment includes a new type of crystallization tank, a diaphragm filter and advanced automatic control system. It uses a scientific cooling and crystallization process to improve the yield of liquid palm oil.

Get Inquiry

Winterization/fractionation/dewaxing_Winterization machine

Palm oil fractionation plant can process palm oil and palm kernel oil.Winterization dewaxing machine can process rice bran oil,sunflower oil,corn germ oil.oil fractionation Winterization dewaxing machine manufacturer.

Get Inquiry

Dewaxing Process, Oil Dewaxing Process, Sunflower Oil

The reason for hazy appearance is due to the precipitation of dissolved waxes. The presence of wax makes the oil appear cloudy at room temperature. The oil normally becomes cloudy in 5-6 h but with proper dewaxing the oil remains clear after 24h of storage at 0?C. Dewaxing is carried out by chilling the oil up to 10-15¡«C into the crystallizers.

Get Inquiry

Professional Winterization Process - Offerd by Oil Mill Machinery

Winterization. Winterization of oil is a process of removing of the higher melting point parts from oil like waxes or triglycerides. It is also a process of removing components with high melting point (e.g waxes) from some vegetable oils, e.g. sunflower, rice bran and cotton seed oil or partially hydrogenated soya bean oil.

Get Inquiry

Oil Dewaxing for Vegetable Oil Refinery Plant

Oil Dewaxing. Oil dewaxing, also called winterization, is typically used at corn and sunflower-processing vegetable oil refineries. It improves the oil's clarity and brightness by removing solids ¨saturated glycerides or waxes¨ that are visible at ambient or low temperatures. KMEC's oil dewaxing machinery reduces the content of these solids

Get Inquiry